Discover how plasma welding delivers speeds 10 times faster than traditional methods, reaches temperatures of 30,000°C, and achieves an efficiency of 90-95%. Ideal for aerospace, automotive & medical industries.

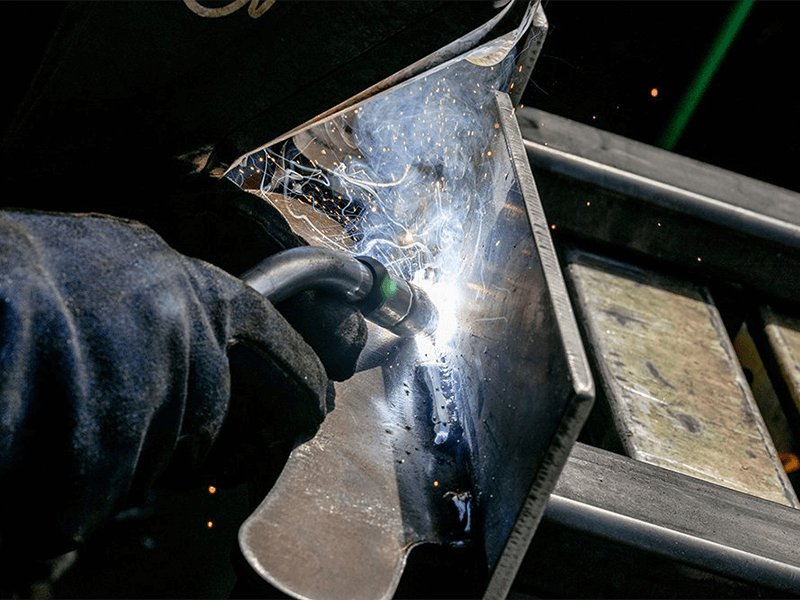

How Plasma Welding Works

Plasma welding initiates when an electric arc ionizes inert gas (argon/hydrogen), creating a superheated plasma jet. Temperatures reach 20,000–30,000°C (4x hotter than the sun’s surface), melting metals with unparalleled precision. The process leverages three stages:

1. Arc Ignition: High-frequency voltage (15,000V) sparks the initial arc.

2. Pilot Arc: Low-voltage (150V) sustains the arc between electrode and nozzle.

3. Main Arc: Transfers to the workpiece, fusing materials at 20,000°C+.

Equipment & Costs

Key Components:

• Power supply (0.1–300 Amps, 60–80V)

• Plasma torch with tungsten electrode

• Inert gas supply (argon or argon/helium mix)

• High-frequency generator

Investment: Professional systems cost 2,000–10,000, excluding consumables (electrodes, gas).

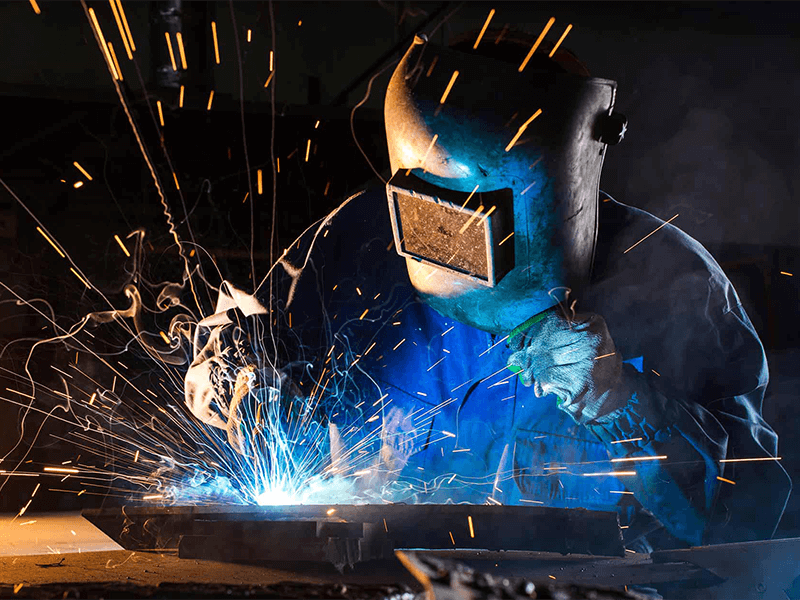

Key Advantages

1. Speed & Efficiency

• 10x faster than TIG welding.

• 85–95% energy efficiency minimizes waste and production time.

2. Pinpoint Precision

• Concentrated arc reduces heat-affected zone (HAZ) to <1mm, preventing distortion.

3. Industrial Applications

• Aerospace, medical devices, and automotive manufacturing (high-integrity welds).

Limitations & Challenges

• High startup cost vs. alternatives like MIG or TIG.

• Requires skilled operators for setup and maintenance.

• Less effective on thick materials (>10mm) or large weld beads.

Plasma Welding vs. Alternatives

| Method | Speed | Precision | Cost | Amperage |

| Plasma Welding | 500 mm/min | Excellent | 2,000–10,000 | 0.1–300A |

| GTAW (TIG) | Moderate | High | 1,000–5,000 | 5–300A |

| GMAW (MIG) | Fast | Moderate | 500–2,000 | 40–500A |

Critical s ParametersProces

• Current: Higher amps = deeper penetration.

• Gas Flow: 0.5–4 L/min (optimal arc stability).

• Travel Speed: >300 mm/min reduces HAZ but requires precision.

• Electrode Maintenance: Worn electrodes cause arc instability.

Optimizing Efficiency

• Heat Transfer: 20,000–30,000°C plasma achieves 85% thermal efficiency.

• Material Compatibility: Best for stainless steel, titanium, and exotic alloys.

• Speed Control: Maximizes productivity while minimizing HAZ.

Related Articles

Best Basic Welds

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necess

Are Cheap Gasless MIG Welders Any Good

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls

The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Mastering MIG And TIG Welding: 5 Essential Torch Techniques for Flawless Results

Welding is an art that combines precision, skill, and a deep understanding of materials. Whether you're an experienced professional or a beginner, refining your torch techniques in MIG and TIG welding can elevate your work from functional to exceptional. Here are five key methods to help you achieve

MIG Vs TIG Welding: Which Process Is Right For Your Project?

MIG welding offers beginner-friendly speed on thicker metals. TIG welding delivers precision on thin metals. Compare costs, speeds, applications & choose wisely.IntroductionMIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding serve distinct purposes. MIG excels at rapid, cost-effective welds o

Which Weld Is The Strongest?

Choosing the optimal welding technique requires understanding different process characteristics. Here's a breakdown of key methods:1. Gas Metal Arc Welding (GMAW / MIG Welding)•What it is: A semi-automatic or automatic process using a continuous, consumable wire electrode and shielding gas.•Key Bene