MIG welding offers beginner-friendly speed on thicker metals. TIG welding delivers precision on thin metals. Compare costs, speeds, applications & choose wisely.

Introduction

MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding serve distinct purposes. MIG excels at rapid, cost-effective welds on thicker mate

rials, while TIG specializes in ultra-precise, clean joins on thin or delicate metals. Below, we break down their differences to help you select the ideal process.

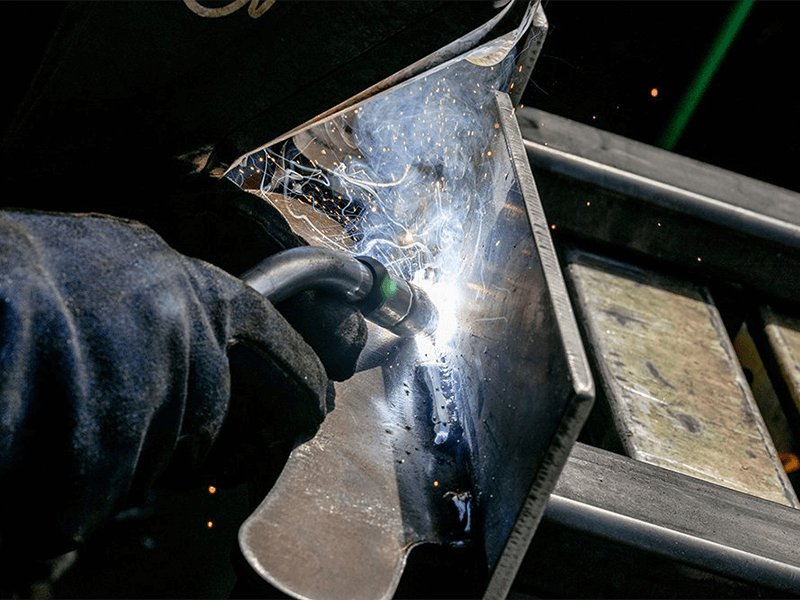

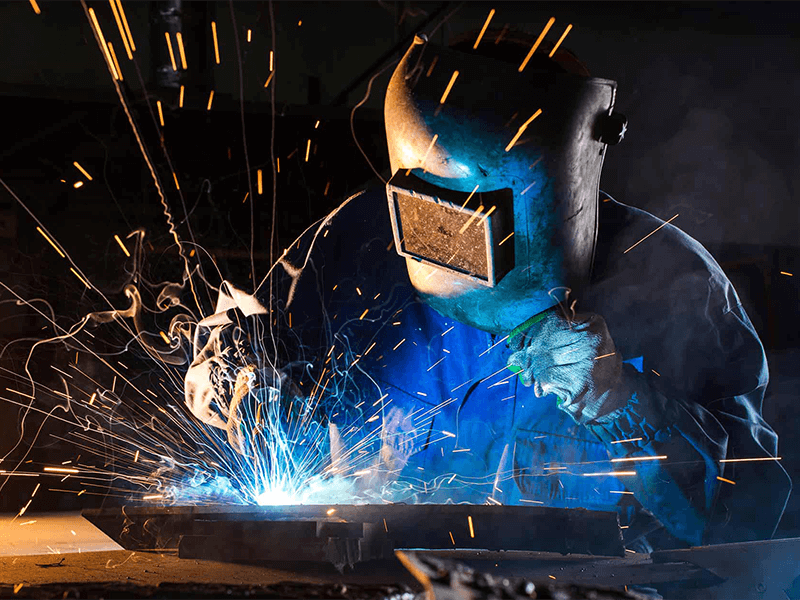

MIG Welding: Speed & Versatility

Overview:

Also known as GMAW (Gas Metal Arc Welding), MIG uses a continuously fed consumable wire electrode shielded by an inert gas (typically Argon/CO² mix). The wire melts into the weld pool, creating strong joins quickly.

Key Features:

•⚡ Speed: 30–120 inches per minute (experienced welders)

•⚙️ Materials: Ideal for steel, stainless steel, aluminum

• Cost: 25–50/hour for professional services

• Power: 115–230V machines | 60–500A amperage range

•⏳ Equipment Lifespan: 7–10 years (extendable with maintenance)

•✅ Best For: Beginners | Thick metal projects | Production environments

TIG Welding: Precision & Quality

Overview:

Also called GTAW (Gas Tungsten Arc Welding), TIG employs a non-consumable tungsten electrode with pure Argon shielding. Filler metal is added manually for unmatched control.

Key Features:

• Precision: Superior finish on thin metals (down to 0.005")

• Speed: 1–5 inches per minute (experienced welders)

• Quality: Aerospace-grade welds with minimal spatter

• Cost: 40–75/hour for professional services

• Power: 230–460V machines | 10–200A amperage range

•⏳ Equipment Lifespan: 10–15 years (with maintenance)

•✅ Best For: Delicate metals | Cosmetic welds | Experienced welders

MIG vs TIG: Critical Differences Compared

| Factor | MIG Welding | TIG Welding |

| Skill Level | Beginner-friendly | Steep learning curve |

| Metal Thickness | Thick sections (≥24ga) | Thin/delicate materials (<18ga) |

| Weld Speed | 5–8x faster | Slow, meticulous |

| Outdoor Use | Wind compromises the gas shield | More wind-resistant |

| Project Cost | Lower machine & labor cost | Higher machine & labor cost |

| Weld Aesthetics | Good, may need cleanup | Museum-quality finish |

How to Choose: MIG or TIG?

1️⃣ Prioritize MIG if you need:

Fast production on thick metals

Beginner-friendly operation

Lower project costs

2️⃣ Choose TIG when you require:

Flawless welds on thin materials (<1/8")

Maximum control for complex joints

Zero-tolerance for cosmetic defects

Related Articles

Best Basic Welds

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necess

The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Mastering MIG And TIG Welding: 5 Essential Torch Techniques for Flawless Results

Welding is an art that combines precision, skill, and a deep understanding of materials. Whether you're an experienced professional or a beginner, refining your torch techniques in MIG and TIG welding can elevate your work from functional to exceptional. Here are five key methods to help you achieve

Which Weld Is The Strongest?

Choosing the optimal welding technique requires understanding different process characteristics. Here's a breakdown of key methods:1. Gas Metal Arc Welding (GMAW / MIG Welding)•What it is: A semi-automatic or automatic process using a continuous, consumable wire electrode and shielding gas.•Key Bene

MIG Vs. FCAW Welding: Key Differences & Application Scenarios

MIG welding requires external gas and is cleaner, ideal for thin materials. FCAW is versatile, self-shielded, better for thick materials and outdoor use, faster, and less sensitive to surface contaminants. Table of Contents Toggle Electrode TypeShielding GasUsability and ApplicationPerformance in Di