News

Best Basic Welds

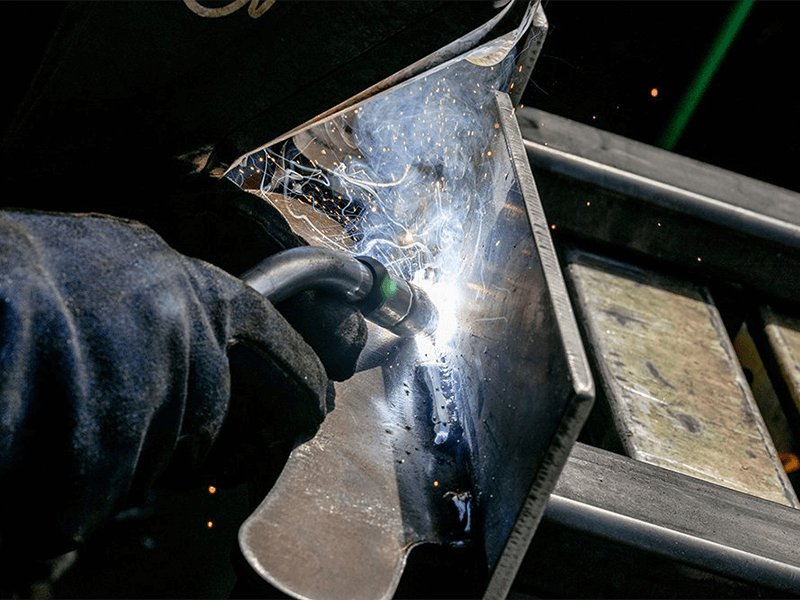

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necess

Read More →Are Cheap Gasless MIG Welders Any Good

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls

Read More →The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Read More →Features of Cheap Gasless MIG Welder

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minut

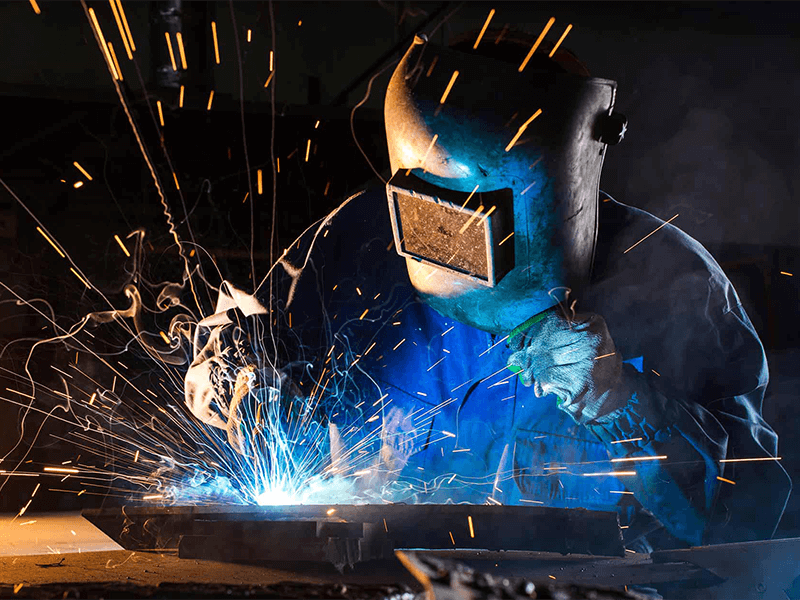

Read More →MIG Welding Basics

MIG welding, also known as gas metal arc welding (GMAW), is an efficient and versatile welding technique used across a wide range of industries. The method uses a continuously fed wire as the electrode and a gas mixture to protect the weld pool from contamination. MIG welding is favored for its high

Read More →4 Major Drawbacks of Using Acetylene

Acetylene’s disadvantages include being highly flammable (with a 2.5%-82% range), unstable above 15 psi, higher costs ($200/month vs. $100 for propane), and toxicity that requires $1,500 detectors.Section 1: High FlammabilityKeywords: acetylene flammable, acetylene explosion risk, welding safety, in

Read More →Cathodic Cleaning in MAG Welding: Mechanism And Practical Applications

Cathodic Cleaning in MAG Welding: Mechanism and Practical ApplicationsThe “cathodic cleaning” effect—often viewed as a near-magical phenomenon in welding—refers to the rapid removal of surface oxides during the arc welding process, resulting in a clean, bright metal surface. While this effect is wel

Read More →TIG Vs MIG Welding for Steel: Which Is Better?

When welding steel, TIG welding is often the preferred method for achieving high precision, clean welds, and controlled heat input. MIG welding, on the other hand, offers greater speed and is better suited for thicker materials or long continuous welds. For thin steel and high-integrity applications

Read More →Double Arcing in Plasma Arc Welding: Causes, Risks, and Prevention

Plasma arc welding is renowned for its precision and deep penetration, earning it the nickname "laser scalpel" of welding. However, this high-precision process is vulnerable to a dangerous phenomenon known as double arcing, where the main arc splits into two separate paths—posing serious risks to we

Read More →The Mystery of Lag Discoloration in Titanium Welding: Causes And Solutions

In titanium welding, the weld color serves as a critical visual indicator of gas protection quality. However, a phenomenon known as "lag discoloration"—where the weld appears silver-white initially but gradually turns gold, blue, or gray during cooling—signals underlying contamination that can sever

Read More →How To Solve The Problem of Spheroidization in Aluminum MIG Welding Wire?

Solving Aluminum MIG Welding Wire Balling: Causes and Smart SolutionsAluminum is widely used in high-end manufacturing, such as aerospace and new energy vehicles, due to its lightweight and corrosion resistance. However, aluminum MIG welding often faces a frustrating issue—wire balling, where the wi

Read More →Why AC Current Is Essential for Aluminum Welding?

Aluminum is everywhere—from smartphones and laptops to aerospace components—valued for its light weight, corrosion resistance, and aesthetic appeal. However, welding aluminum presents unique challenges that often require alternating current (AC) rather than direct current (DC). Here’s why.The Challe

Read More →