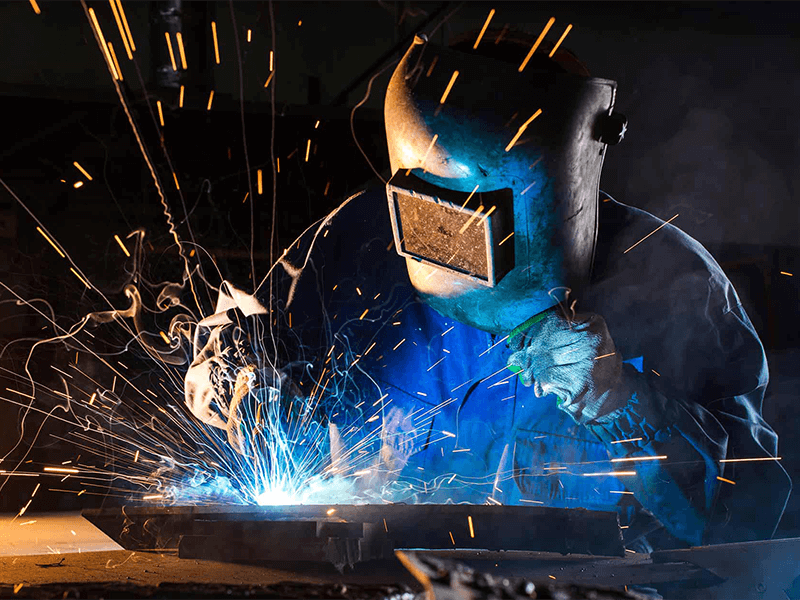

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessary structural safety. This type of welding is popular because it is simple and efficient, as fillet welds do not require the precise edge preparation that some welding methods do. In addition, fillet welds are best suited to joining smaller metal pieces: for example, brackets, wiring, and small pipes used in residential construction and repair.

The first advantage of fillet welding is related to cost. Fillet welding is efficient in that it requires less welding material than, for example, more expensive welding technologies combined. Fillet welding does not require expensive materials, which makes it an effective method in large-scale construction. The cost difference is obvious: the filler material required for a standard fillet weld is about 25% of the filler material required for a Hicks groove weld of the same size.

The second advantage is the speed of construction. Experienced workers can complete and lay fillet welds faster than other welding types, and the increase in welding speed increases industrial productivity and reduces labor costs. Finally, I think fillet welds have a higher quality and joint strength. If the right materials and techniques are used, the actual strength of a fillet weld can be equal to or greater than the original strength of the object being welded.

Related Articles

Are Cheap Gasless MIG Welders Any Good

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls

The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Features of Cheap Gasless MIG Welder

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minut

MIG Welding Basics

MIG welding, also known as gas metal arc welding (GMAW), is an efficient and versatile welding technique used across a wide range of industries. The method uses a continuously fed wire as the electrode and a gas mixture to protect the weld pool from contamination. MIG welding is favored for its high

4 Major Drawbacks of Using Acetylene

Acetylene’s disadvantages include being highly flammable (with a 2.5%-82% range), unstable above 15 psi, higher costs ($200/month vs. $100 for propane), and toxicity that requires $1,500 detectors.Section 1: High FlammabilityKeywords: acetylene flammable, acetylene explosion risk, welding safety, in

Cathodic Cleaning in MAG Welding: Mechanism And Practical Applications

Cathodic Cleaning in MAG Welding: Mechanism and Practical ApplicationsThe “cathodic cleaning” effect—often viewed as a near-magical phenomenon in welding—refers to the rapid removal of surface oxides during the arc welding process, resulting in a clean, bright metal surface. While this effect is wel