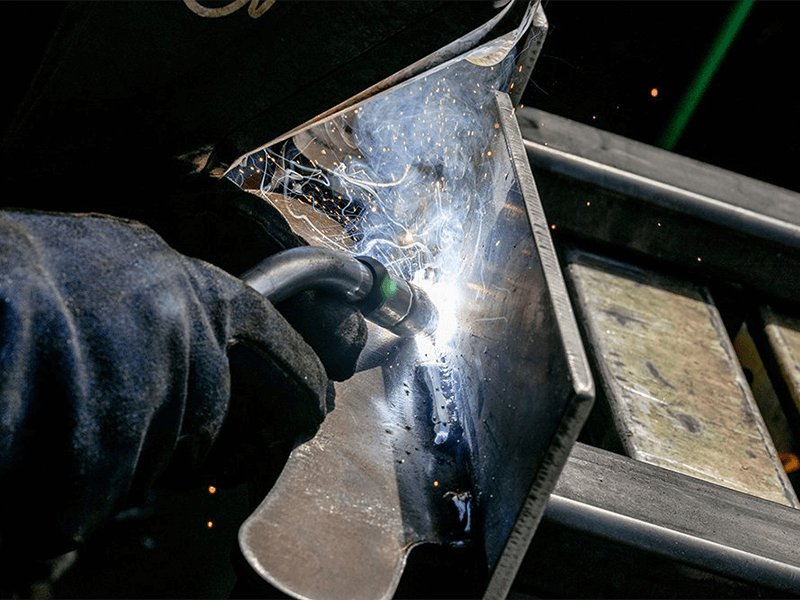

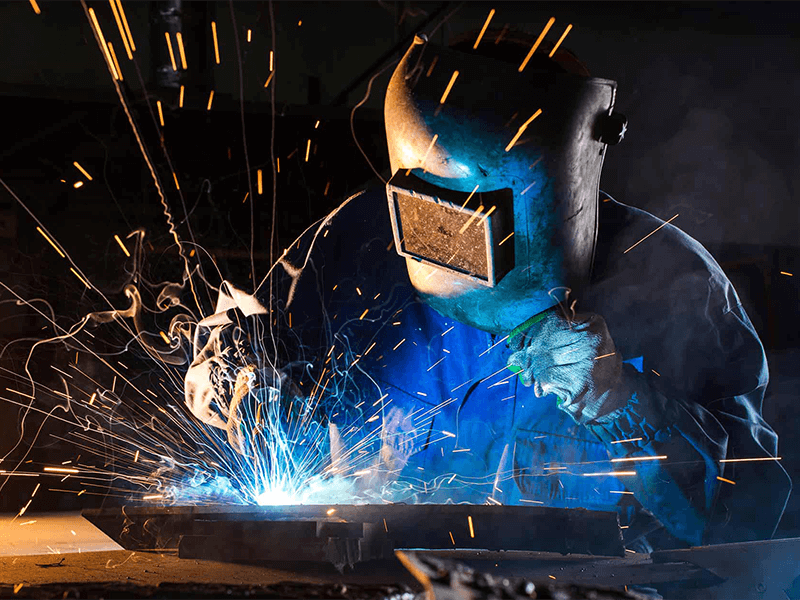

Welding is an art that combines precision, skill, and a deep understanding of materials. Whether you're an experienced professional or a beginner, refining your torch techniques in MIG and TIG welding can elevate your work from functional to exceptional. Here are five key methods to help you achieve cleaner, stronger, and more professional welds.

1. The "Cursive E" Technique for MIG Welding

Key points: Maintain a steady rhythm without sudden movements. Benefit: Produces uniform weld beads with improved appearance and strength.

2. The Crescent Moon Technique for Better Penetration

Application: Best used on joints requiring deeper weld penetration. Tip: Keep movements fluid to avoid creating irregularities in the bead.

3. Torch Angle Adjustment for TIG Welding

Why it matters: Prevents contamination and supports arc focus. Pro tip: Angle the tungsten slightly toward the welding direction for improved control.

4. Arc Length and Distance Control

TIG Welding: Keep a distance of 1/8″ to 3/16″ between the tungsten and the workpiece. MIG Welding: Adjust the wire-to-work distance to balance penetration and bead shape. Too close: Risk of sticking or splatter. Too far: Unstable arc and weak penetration.

5. Two-Handed Torch Control for Stability

MIG Welding: Use one hand to grip the torch and the other to support the neck or cable. TIG Welding: Feed the filler rod with your non-dominant hand while controlling the torch with your dominant hand. This approach reduces shaking and results in smoother, more consistent welds.

Final Tips to Improve Your Welding

Practice Regularly: Mastery comes with repetition. Use scrap material to refine each technique. Monitor Heat Management: Adjust amperage and travel speed to match material thickness. Use Quality Gear: A responsive torch, proper gas, and clean consumables make a noticeable difference.

Related Articles

Best Basic Welds

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necess

Are Cheap Gasless MIG Welders Any Good

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls

The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Manual vs. Robotic Welding: Key Differences and Applications

Manual welding relies on human skill to perform joins, while robotic welding utilizes programmed machinery to achieve precision and efficiency. Understanding the distinctions between these methods helps in selecting the right approach for specific projects.Precision and ConsistencyManual Welding: Qu

Do You Need a Mask for Plasma Cutting?

Yes, wearing proper respiratory protection is essential when operating a plasma cutter. A well-chosen mask protects operators from hazardous fumes, airborne particles, and indirect radiation exposure, making it a non-negotiable part of plasma cutting safety protocols.Primary Hazards of Plasma Cuttin

How Cost-effective Is The Hot Wire TIG System?

Tungsten Inert Gas (TIG) welding is celebrated for its ability to create exceptionally clean and high-integrity welds. A key factor limiting its wider application on thicker materials, however, is its relatively slow speed. Hot Wire TIG welding addresses this limitation head-on, representing an adva