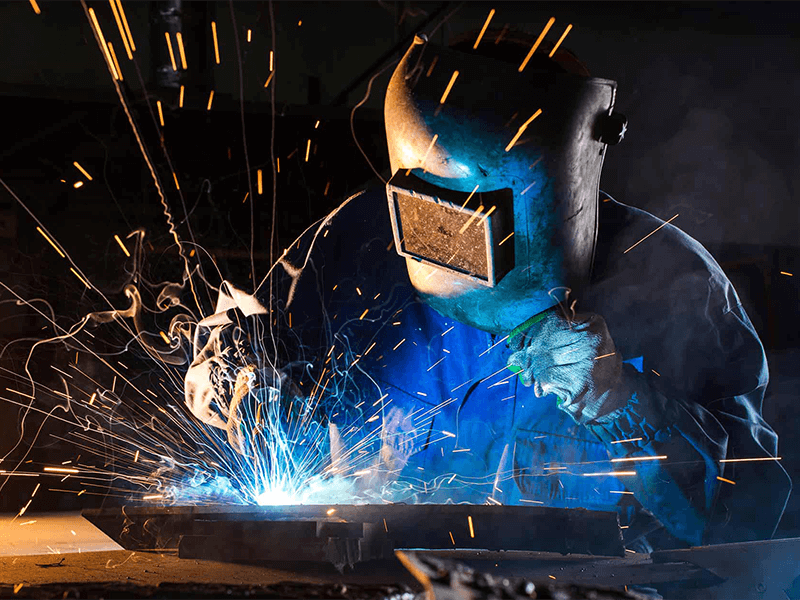

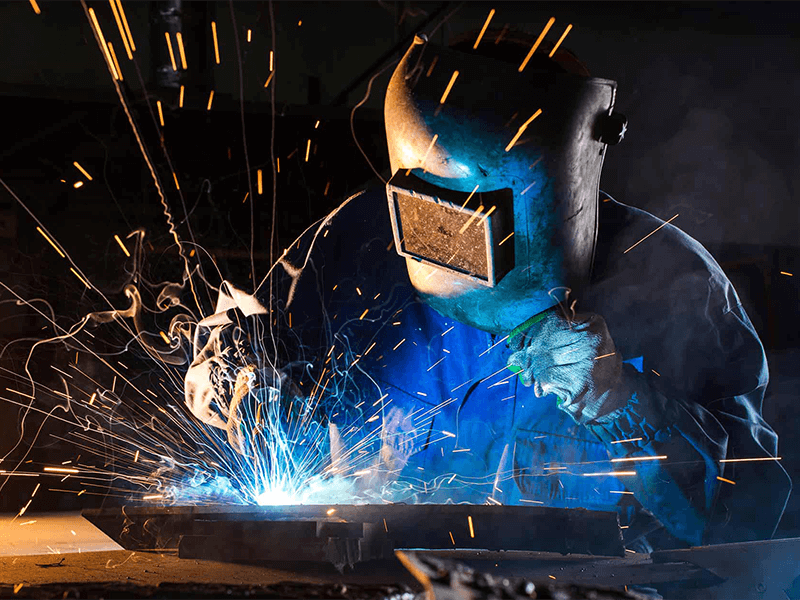

19 Years Of Welding Technology Accumulation

Established in 2006, Innotec is a professional manufacturer and service provider specializing in research, production, and sales of Welding Torches.

Serving 2000+ Industrial Enterprises

Due to our extensive reach and impact, we proudly serving over 2,000 industrial enterprises across diverse sectors.

113 Technical Patents

Innotec invests 20% of its profits in research and development every year. Currently, we have applied for 113 technical patents.

2 Major Service Centers Nationwide

We focus on innovating and creating valve together with our business partners.

35+ Highly Sophisticated R&D Personnel

Innotec maintains a leading position in research and development capabilities in the chinese welding sector.

40,000㎡ Factory Area

with an area coverage of 40,000 m², Innotec now has over 300 machine tools,our yearly production capacity is over 2,500,000 pcs.

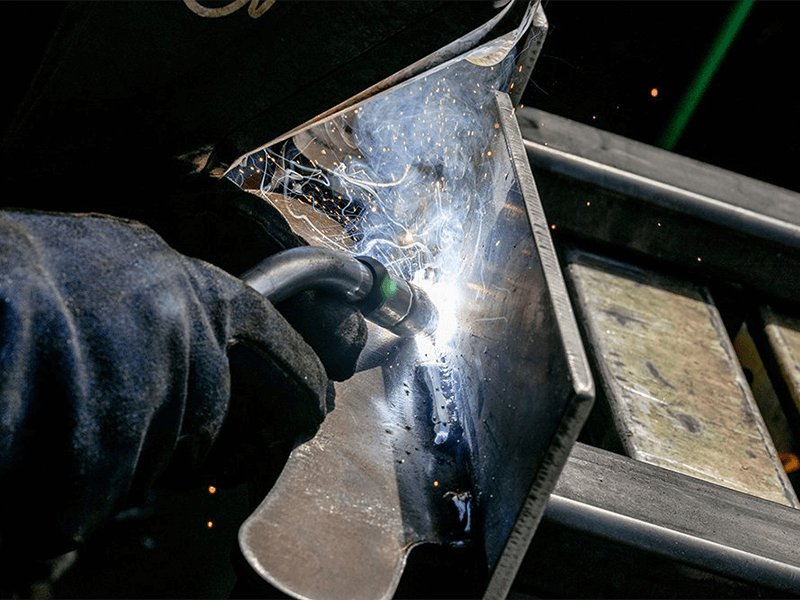

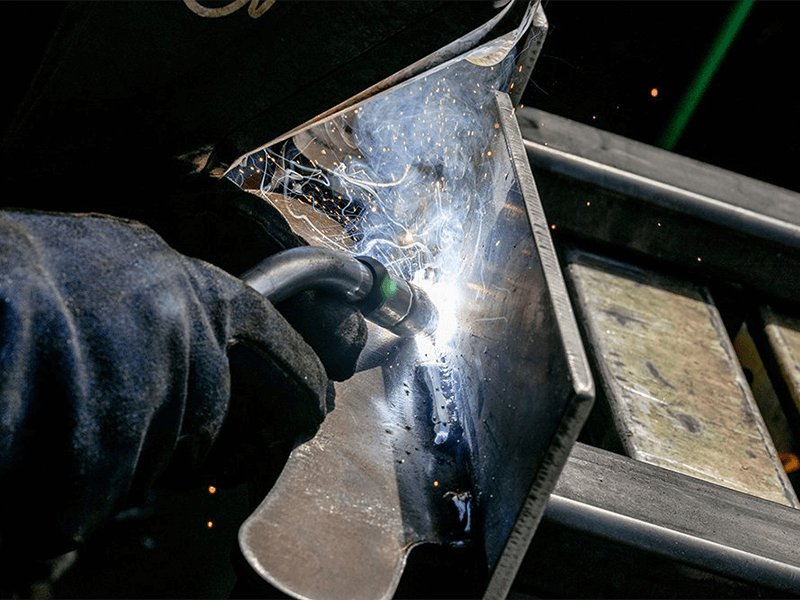

Ergonomic MIG welding guns ensure low-spatter, high-speed joins for steel, aluminum, and stainless steel.

Precision TIG welding torches deliver clean, spatter-free welds on stainless steel, aluminum, and titanium.

Industrial-grade plasma cutting torches ensure precision, high-speed slicing on steel, stainless steel, and aluminum.

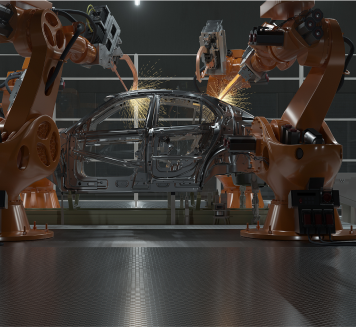

Robotic welding torches ensure precision high-speed automation for automotive and heavy industry.

Differentiation

Product Performance Differentiation Specialist Of You

Targeting three critical operations in pipeline construction — circumferential seam welding for high-strength pipelines, hot tapping under pressure, and precision bevel cutting — we offer a dual-standard process system certified to both API and ASME.

Focusing on three critical scenarios in shipbuilding — longitudinal stiffener welding on shell plates, circumferential seam welding during grand block assembly, and precision cutting of thick plates...

Addressing three heavy-fume industrial welding conditions — enclosed space welding, high-current continuous operations, and heavy component manufacturing — we offer fume extraction solutions fully compliant with EN 1093-5 and ISO 15012 standards.

As the wind power industry moves toward larger-scale and offshore development, welding and cutting technologies face unprecedented challenges: tower heights exceeding 150 meters, single-unit capacities reaching 15 MW, and harsher offshore corrosion environments.

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Latest Technology Trends

Latest Technology Trends

Latest News

Dynamic Content Area

-

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessArticle

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessArticle -

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controlsArticle

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controlsArticle -

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding GaArticle

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding GaArticle

An Important Step In The Overall Development

Welcome To Email Us!