Innotec TIG Welding Torch Manufacturer

Engineered for Precision, Built for Endurance – Directly from Our Factory

Since 2006, Innotec has supplied over 80 countries with TIG welding torches that excel in:

· Highly Efficient and Continuous Operation

An optimized cooling system effectively prevents the welding gun from overheating, enabling long, high-current welding sessions and ensuring high productivity.

· User-Friendly Operation

The lightweight design and ergonomic structure significantly reduce operator fatigue from prolonged use, enhancing working comfort and maneuverability.

· Excellent Welding Performance

Precisely engineered gas shielding and current conduction, coupled with stable wire feeding, ensure extremely stable arc flow, effectively reducing weld spatter for cleaner welds and saving processing time.

· Rugged and Durable for Harsh Environments

Key components, such as the torch head and nozzle, are constructed from heavy-duty, durable materials. The housing and cable sheath are rugged and wear-resistant, ensuring they withstand the rigors of factory floor use and harsh environments.

Your Professional TIG Welding Torch Supplier in China

Contact Us

Can't Find Ideal TIG Welding Torch For Your Needs?

Why Choose Us

Why is Innotech Your Reliable TIG Torch Manufacturer?

Ergonomic MIG welding guns ensure low-spatter, high-speed joins for steel, aluminum, and stainless steel.

Industrial-grade plasma cutting torches ensure precision, high-speed slicing on steel, stainless steel, and aluminum.

Robotic welding torches ensure precision high-speed automation for automotive and heavy industry.

Industrial-grade consumables: better welds, safer operation.

TIG Welding Torch FAQ

1.Pre-Sales & Procurement Support

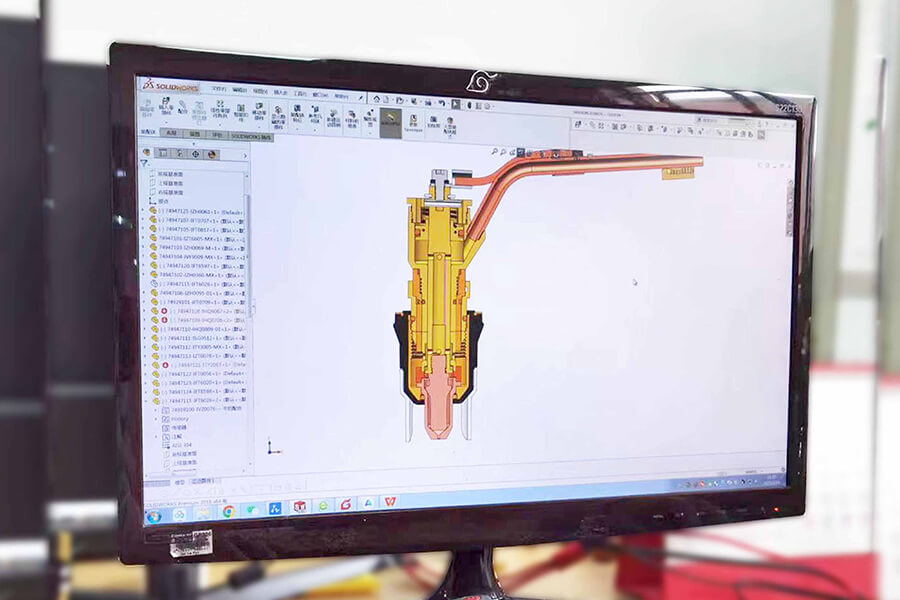

Do you offer complimentary technical consultation or design services?

Yes, our certified engineers provide tailored technical support, including 3D CAD models and prototype validation based on project specifications.

How do you request product quotes or bulk purchase discounts?

Is custom equipment development supported?

2. After-Sales Service & Warranty

What is the warranty period, and what does it cover?

1-year warranty ensures welding performance and airtight integrity of core components. Consumables (e.g., nozzles, contact tips) are excluded.

How to report malfunctions, and what is the response time?

Do you provide repair or spare parts replacement?

3. Logistics & Delivery

What is the lead time, and do you offer expedited delivery?

Standard lead time is 30-45 days after order confirmation. Priority production slots are available for urgent projects.

Do you handle global shipping and customs clearance?

4. Training & Technical Support

Are operation manuals or training materials included?

A detailed multilingual user manual is packed with each product, covering setup, maintenance, and troubleshooting.

Is real-time technical guidance available (e.g., video tutorials or remote assistance)?

5. Environmental & Safety Compliance

Do your products meet eco-standards (emissions/noise control)?

All equipment is CE-certified with RoHS 2.0 compliance, ensuring low emissions and noise levels below 85dB(A).

How to ensure operator safety during welding?

Welcome To Email Us!