Features of Cheap Gasless MIG Welders

Wire Feed Speed

Wire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minute.

Power Settings

Power settings are equally crucial for gasless MIG welders to adjust the welder to different welding tasks. Most cheap models only offer a power output range of 30 to 140 amps. This power level can handle a wide range of welding tasks from light to medium, and is usually sufficient for DIY projects and repairs. However, most general-purpose welders need to increase the power to 200 amps for more demanding tasks to ensure deeper penetration and stronger welds.

Portability and Ease of Use

One of the advantages of cheap gasless MIG welders is their portability. These devices typically weigh 25 to 40 pounds, making them easy to transport and set up. In addition, their design and ease of operation make them user-friendly, especially for beginners. No gas cylinders are required, further enhancing portability as there is no additional equipment to carry. 65

Benefits of Gasless MIG Welders

Cost-Effectiveness

Gasless MIG welders are known for their cost-effectiveness. With an initial investment of as little as $100 to $200 for a basic gasless MIG welder, they are ideal for hobbyists and DIY enthusiasts. In comparison, a traditional MIG welder with a gas unit can cost up to $400. In addition, since no shielding gas is required, there is no ongoing gas refill expense, which can range from $30 to $60 per cylinder.

No Shielding Gas Required

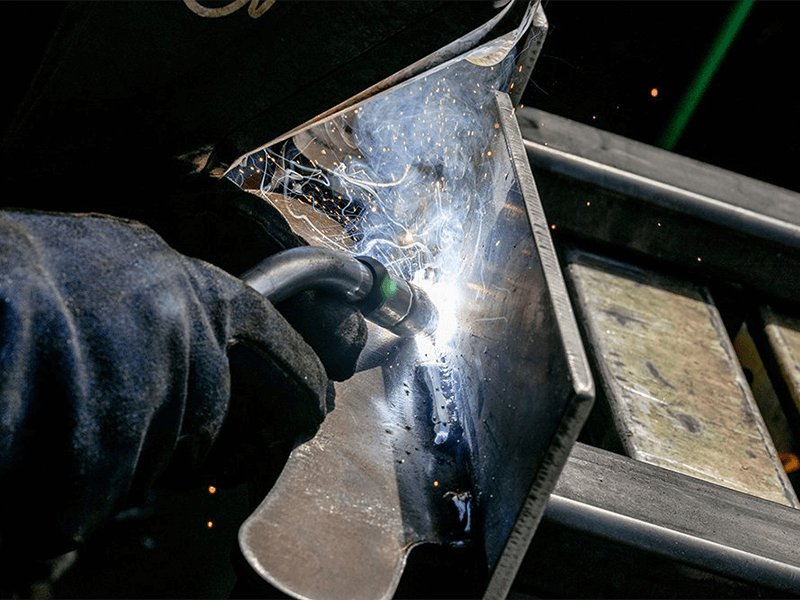

One of the main benefits of gasless MIG welders is that they do not require shielding gas. This not only reduces costs but also simplifies the welding process. The flux-cored wire used in these welders generates its own shielding gas as it heats, protecting the weld pool from contamination. This feature is particularly beneficial for outdoor welding, as wind can disperse the shielding gas used in traditional MIG welding.

Adaptable to Different Environments

Affordable gasless MIG welders are compact and lightweight, making them easy to move and set up between jobs. These machines are also simpler in design and operation, making it easier for beginners to learn welding. These machines do not require gas cylinders, making them very portable, and no additional equipment is required, making the overall package easy to carry.

Related Articles

Best Basic Welds

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necess

The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Features of Cheap Gasless MIG Welder

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minut

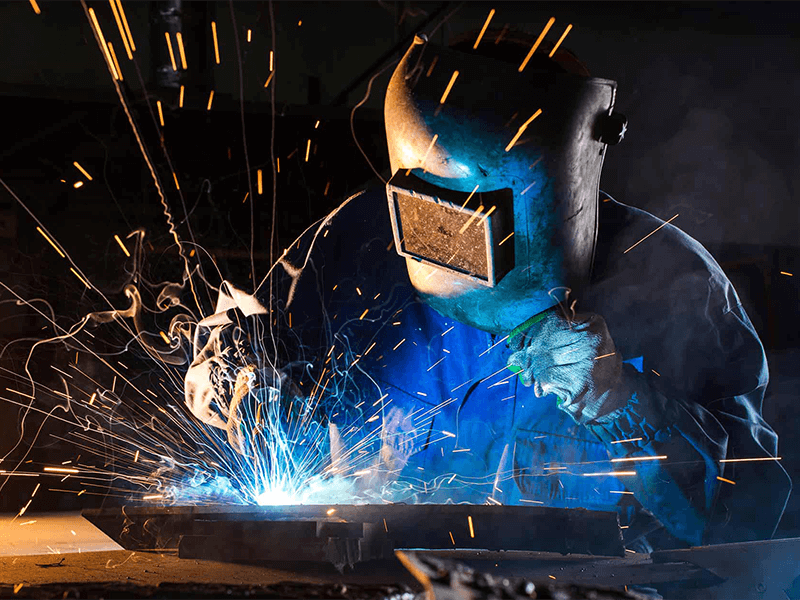

MIG Welding Basics

MIG welding, also known as gas metal arc welding (GMAW), is an efficient and versatile welding technique used across a wide range of industries. The method uses a continuously fed wire as the electrode and a gas mixture to protect the weld pool from contamination. MIG welding is favored for its high

4 Major Drawbacks of Using Acetylene

Acetylene’s disadvantages include being highly flammable (with a 2.5%-82% range), unstable above 15 psi, higher costs ($200/month vs. $100 for propane), and toxicity that requires $1,500 detectors.Section 1: High FlammabilityKeywords: acetylene flammable, acetylene explosion risk, welding safety, in

Cathodic Cleaning in MAG Welding: Mechanism And Practical Applications

Cathodic Cleaning in MAG Welding: Mechanism and Practical ApplicationsThe “cathodic cleaning” effect—often viewed as a near-magical phenomenon in welding—refers to the rapid removal of surface oxides during the arc welding process, resulting in a clean, bright metal surface. While this effect is wel