Industrial-Grade Precision for Demanding Welding Operations

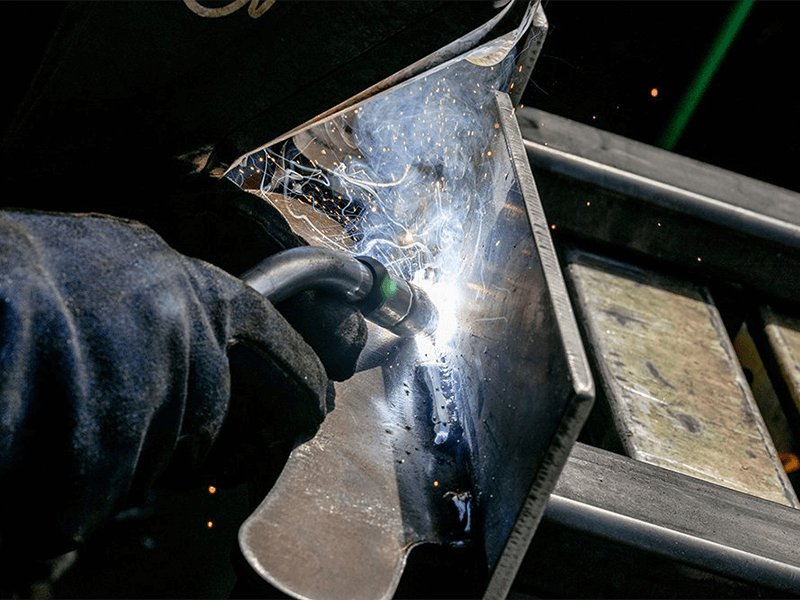

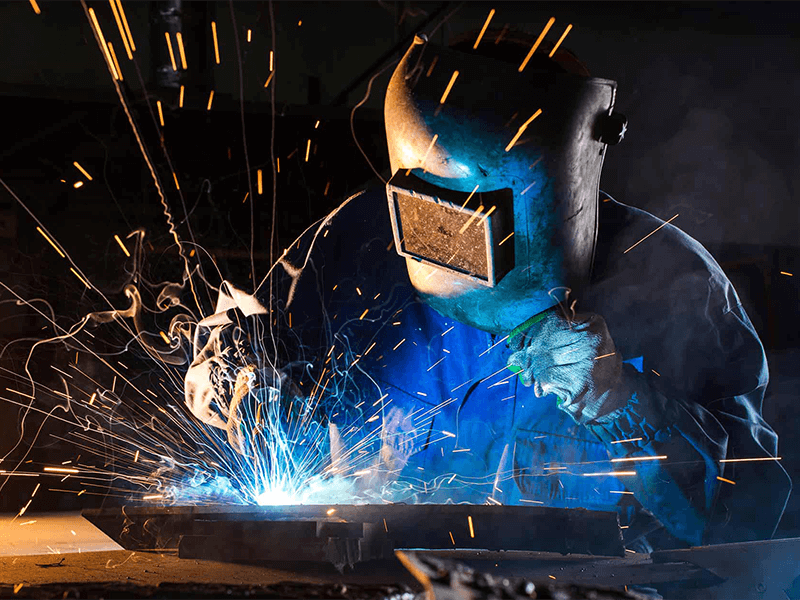

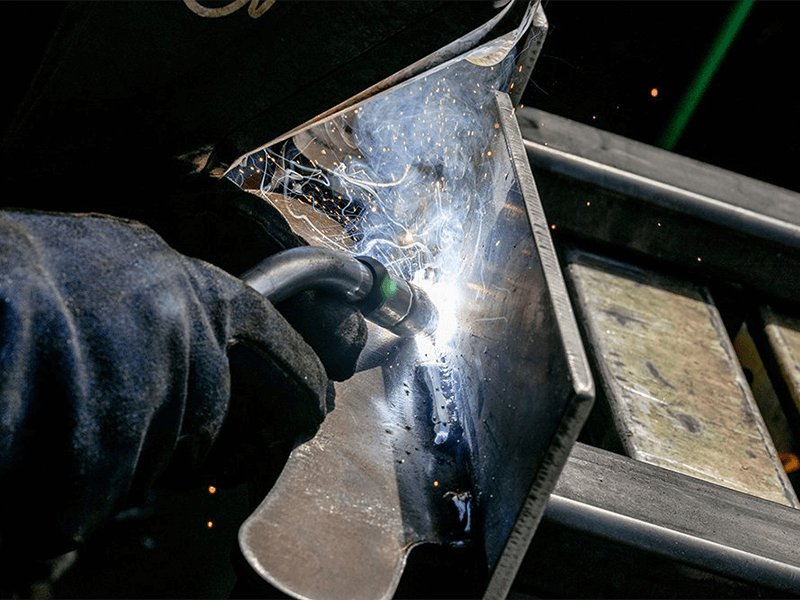

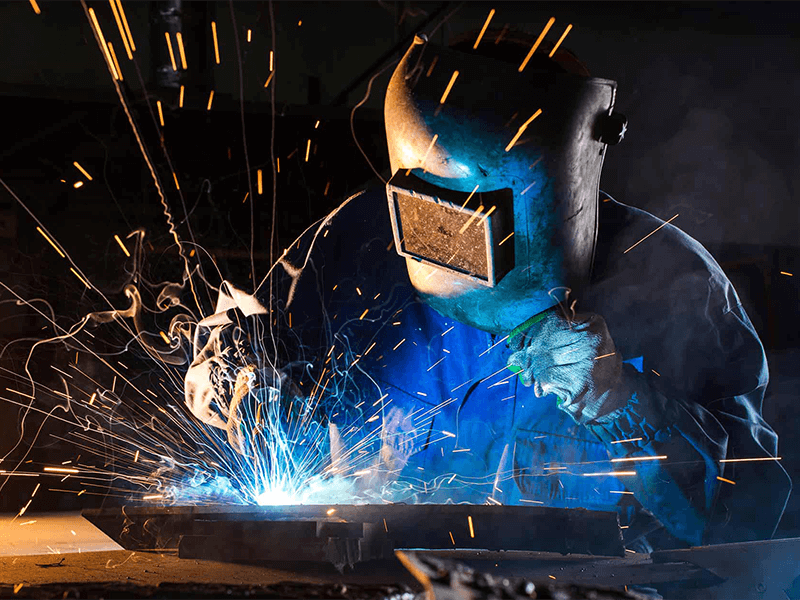

Elevate your production efficiency with the MIG Welding Torch Series, trusted by metal fabricators, automotive manufacturers, and heavy machinery workshops worldwide. Engineered for high-amperage performance and extreme durability, these torches deliver flawless arc stability, reduced spatter, and unmatched operator comfort—ideal for 24/7 industrial environments.

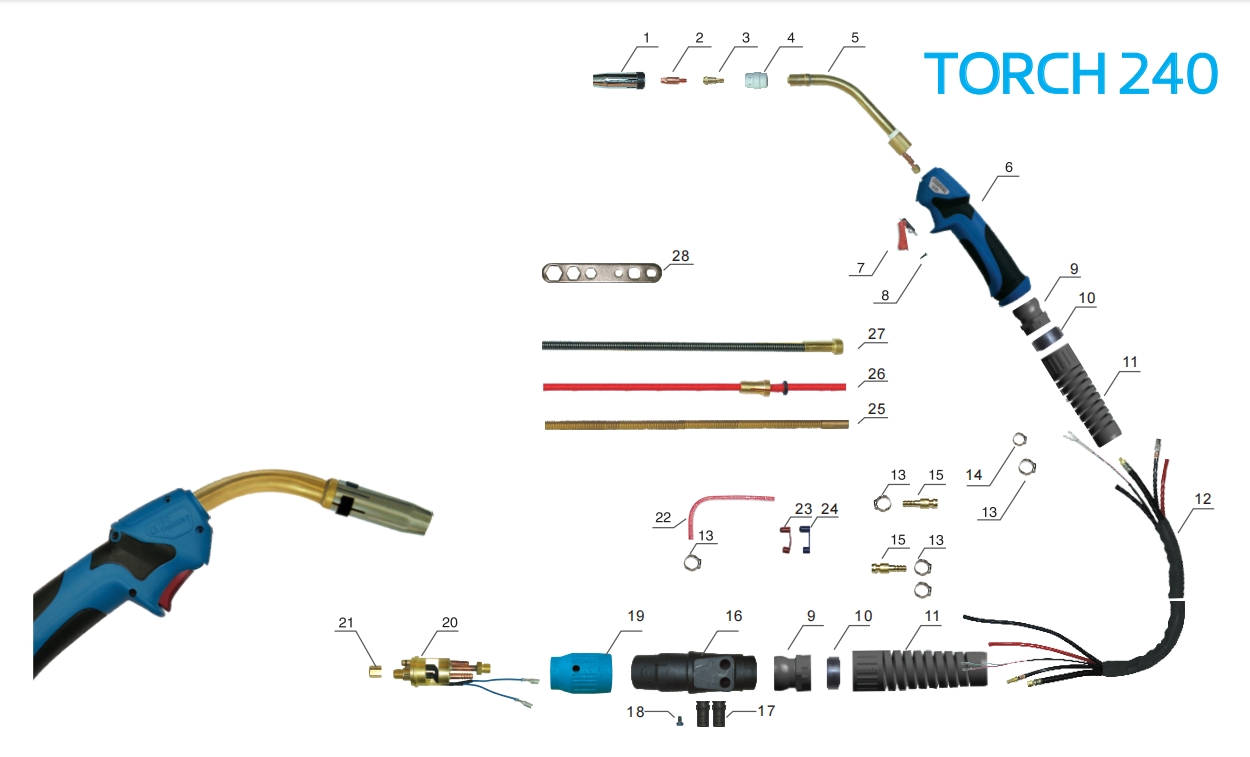

TORCH 240 Technical Data:

ABIMIG® WT Features at a Glance:

Robust Construction

Durably built from the front to the rear. ABIMIG WT's are made for 100% duty cycle welding and rated up to 600 amps for welding thick metal at high deposition rates. For best results use with our ABICOOLER 1300 Water-cooler.

Removable, Rotating Swannecks

ABIMIG WT swannecks are easily rotatable and removable to get welders in the most comfortable position possible. The slim handle and ball socket at the handle base make for the most comfortable welding operation.

Custom Options for Every Job

All ABIMIG WT's come with a variety of swanneck options rated for 500 and 600 amps to give welders the powerful and convenient joint access. All ABIMIG WT's use the high-grade, long-life BINZEL consumables for increased life.

ABIMIG WT Product Videos:

ABIMIG WT Product Overview

ABIMIG WT Product Overview

How-To: Connector Kit Installation

How-To: Wire Liner Replacement

ABIMIG® WT Product Accessories:

ABICOOLER Water-coolers

Get elite protection of your water-cooled MIG guns in a compact design. ABICOOLER uses an integrated flow switch to monitor the permanent cooling system and ensure optimal welding gun protection.

See ABICOOLER

ABI-Shield Ceramic Spray

Get even more protection of your welding consumables. ABI-Shield and the Ceramic Coating Cap need just one spray for over 6 hours of protection for your contact tips and nozzles from weld spatter buildup.

See ABI-Shield Ceramic Spray

Recommended Reading:

-

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessArticle

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessArticle -

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controlsArticle

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controlsArticle -

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding GaArticle

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding GaArticle -

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minutArticle

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minutArticle

Product Resources

Catalog, Ordering Chart, & Manual

Grab Your Free Catalog Now! Discover Welding Magic at Your Fingertips – Click, Download, Geek Out on Innovation!

Replacement Parts

| Position | Code | Ref. | Description |

| 1 | ICS0806 | 145.0080 | GAS NOZZLE Φ12,5 24KD |

| 2 | ICU0004-10 | 140.0242 | CONTACT TIP/1.0/M6*28 |

| 3 | ICU0683 | 142.0003 | CONTACT TIP HOLDER 24KD M6 26MM |

| 4 | ICF0539 | WHITE CERAMIC GAS DIFFUSER 24KD | |

| 5 | ICI0091 | 023.0001 | TORCH HEAD 240 |

| 6 | ICV0890-01 | MIG GRIP HANDlE/BLUE BODY AND BLACK RUBBER/NON LOGO/ | |

| 7 | IHQ0070 | 185.0031 | TRIGGER RED 21.8MM |

| 8 | IFT0874 | SCREW D.3x10 UNI9707 | |

| 9 | IHJ0021 | BALL JOINT | |

| 10.1 | IHJ0852 | CLOSING RING RING/BIG/INSIDE | |

| 10.2 | IHJ0855 | CLOSING RING/PLASMA BACK BOX HOLE/BIG | |

| 11 | IFT0822 | SPRING CABLE SUPPORT/WATER | |

| 12 | ICD0067 | CABLE ASSEMBLY 3M 401D-501D | |

| 13 | IFT0722 | CLAMP Φ9MM | |

| 14 | IFT0730 | CLAMP Φ8MM | |

| 15 | IZT8070-02 | 190.0099 | QUICK CONNECTOR WATER Φ6/APH/190-0099 |

| 17 | IHJ0763 | HOSE SUPPORT FOR WATER COOLING BACK BOX HOLE | |

| 18 | IFT0063 | SCREW M4X6 UNI 6107 | |

| 19 | IHJ0072 | GUN PLUG NUT NEW BLUE | |

| 20 | ITB0057 | 501.2156 | WATER EURO CENTRAL ADAPTER BODY/SPRING PINS |

| 21 | IZT0071 | 501.0082 | LINER NUT |

| 22 | IKH0605 | EPDM WATER TUBE D.5x8 RED/BLACK | |

| 23 | IHJ0306 | PLASTIC SUPPORT FOR WATER COOLING CONNECTOR RED | |

| 24 | IHJ0308 | PLASTIC SUPPORT FOR WATER COOLING CONNECTOR BLUE | |

| 25 | IIC0220 | BRASS LINER 4.0X2.0 0.35M | |

| 26 | IIC0160 | 126.0005 | TEFLON LINER 4.0 X 2.0 3M RED |

| 27 | IIC0571 | 122.0031 | STEEL LINE 1.0-1.2 3.5M |

| 28 | ICG6000 | SPANNER FOR MIG |

| Code | Ref. | Description |

| ICH2598-36 | MIG 240 TORCH 3M/EURO ADAPTER/SPRING PINS/GRIP HANDlE/BLUE | |

| ICH2599-36 | MIG 240 TORCH 4M/EURO ADAPTER/SPRING PINS/GRIP HANDlE/BLUE | |

| ICH2595-36 | MIG 240 TORCH 5M/EURO ADAPTER/SPRING PINS/GRIP HANDlE/BLUE |

* Certified MIG Welding:

RoHS-compliant materials, ISO 9001:2015 quality-controlled manufacturing, CE Marked per EU directives, and EN 60974-7 compliant arc performance. Precision-engineered for global industrial compliance.

Are you ready to experience the special features of welding?

Boost Productivity Today – Experience how welder-centric engineering, industrial-grade consumables, and fatigue-reducing ergonomics elevate weld quality and operators' safety.

Next Steps

✓ Request Custom Quote: Tailored to your amperage, materials, and workflow

✓ Expert Support: Connect with welding engineers for technical guidance

Engineered for Results. Trusted Globally.