The Robot W600 welding gun is a general industrial robotic liquid cooled

torch. It has excellent cooling performance, compact structure and good accessibility ensure continuous precision welding.The interchangeable gun necks shorten equipment downtime and reduces the cost of maintenance, It has a high degree of process safety and is capable of welding work between various materials.

PRODUCT ADVANTAGES

- Stainless steel torch neck, strong and durable, without fear of collision

- Anti collision made of high-strength aviation aluminum alloy to ensure accurate "reset accuracy"

- Convenient installation and simple operation

- Available for all hollow welding robots

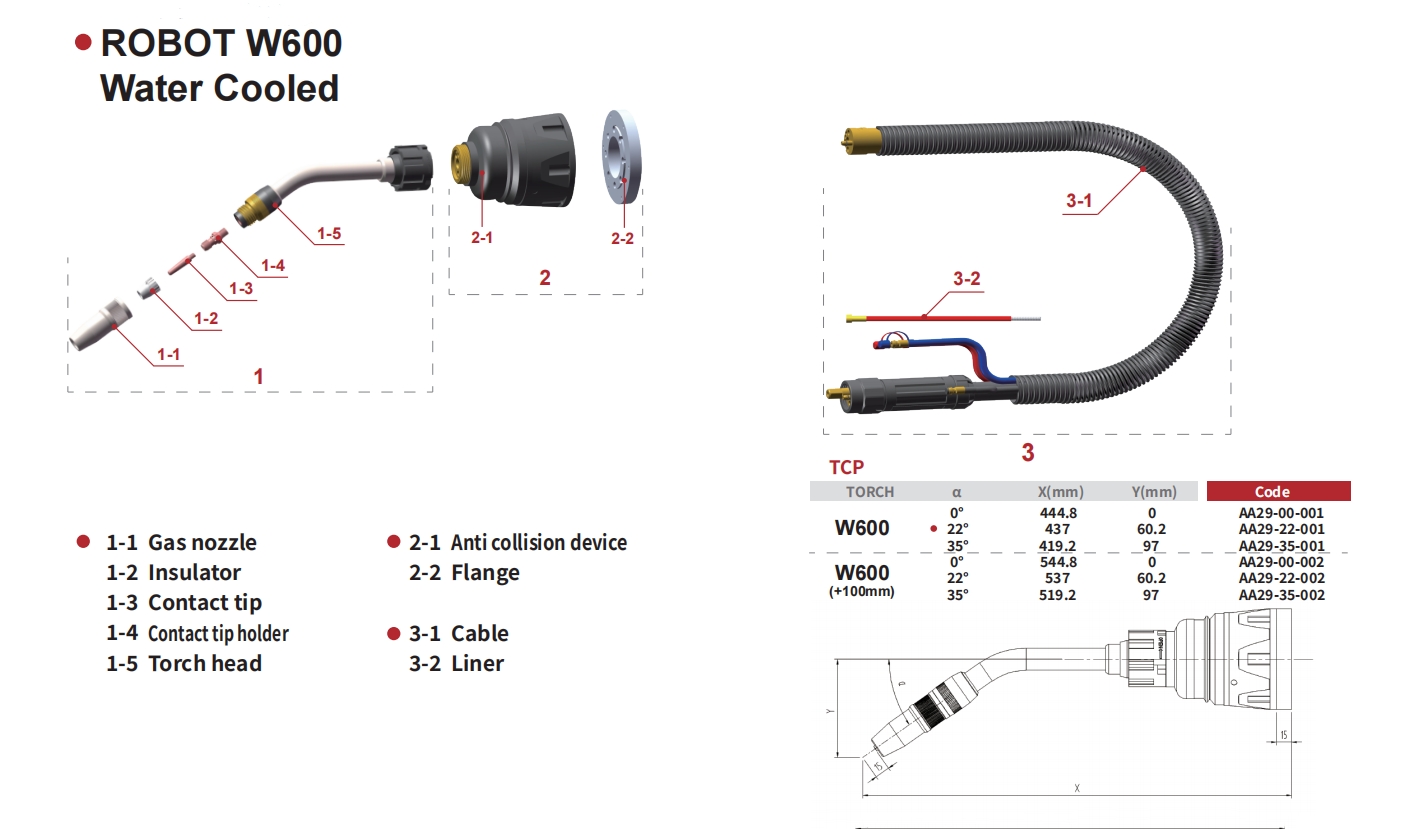

ROBOT W600 Technical Data:

| SPECIFICATIONS | ||

| Cooling mode: | Water-cooled | |

| Rated value: | 600A CO2/550A, MIXED GAS | |

| Duty cycle: | 100% | |

| Diameter of welding wires: | 0.8-1.6mm | |

| Angle of gun neck: | 22° | |

| Instant stop: | The deviation between X axis and Y axis is around1.5° | |

The deviation of the Z axis is around 1mm.

ABIMIG® WT Features at a Glance:

Robust Construction

Durably built from the front to the rear. ABIMIG WT's are made for 100% duty cycle welding and rated up to 600 amps for welding thick metal at high deposition rates. For best results use with our ABICOOLER 1300 Water-cooler.

Removable, Rotating Swannecks

ABIMIG WT swannecks are easily rotatable and removable to get welders in the most comfortable position possible. The slim handle and ball socket at the handle base make for the most comfortable welding operation.

Custom Options for Every Job

All ABIMIG WT's come with a variety of swanneck options rated for 500 and 600 amps to give welders the powerful and convenient joint access. All ABIMIG WT's use the high-grade, long-life BINZEL consumables for increased life.

ABIMIG WT Product Videos:

ABIMIG WT Product Overview

ABIMIG WT Product Overview

How-To: Connector Kit Installation

How-To: Wire Liner Replacement

ABIMIG® WT Product Accessories:

ABICOOLER Water-coolers

Get elite protection of your water-cooled MIG guns in a compact design. ABICOOLER uses an integrated flow switch to monitor the permanent cooling system and ensure optimal welding gun protection.

See ABICOOLER

ABI-Shield Ceramic Spray

Get even more protection of your welding consumables. ABI-Shield and the Ceramic Coating Cap need just one spray for over 6 hours of protection for your contact tips and nozzles from weld spatter buildup.

See ABI-Shield Ceramic Spray

Recommended Reading:

-

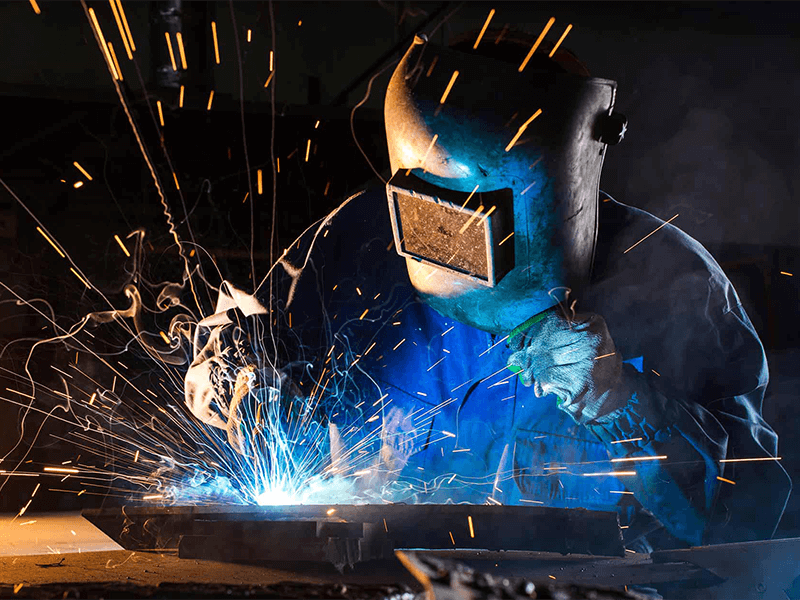

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessArticle

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal at right angles. "Fillet welds also play an important role in the construction of bridges, ships, and various frames," Hicks said. Fillet welds are often the best choice to ensure the necessArticle -

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controlsArticle

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controlsArticle -

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding GaArticle

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding GaArticle -

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minutArticle

Wire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls and can go up to 700 inches per minutArticle

Product Resources

Catalog, Ordering Chart, & Manual

Grab Your Free Catalog Now! Discover Welding Magic at Your Fingertips – Click, Download, Geek Out on Innovation!

Replacement Parts

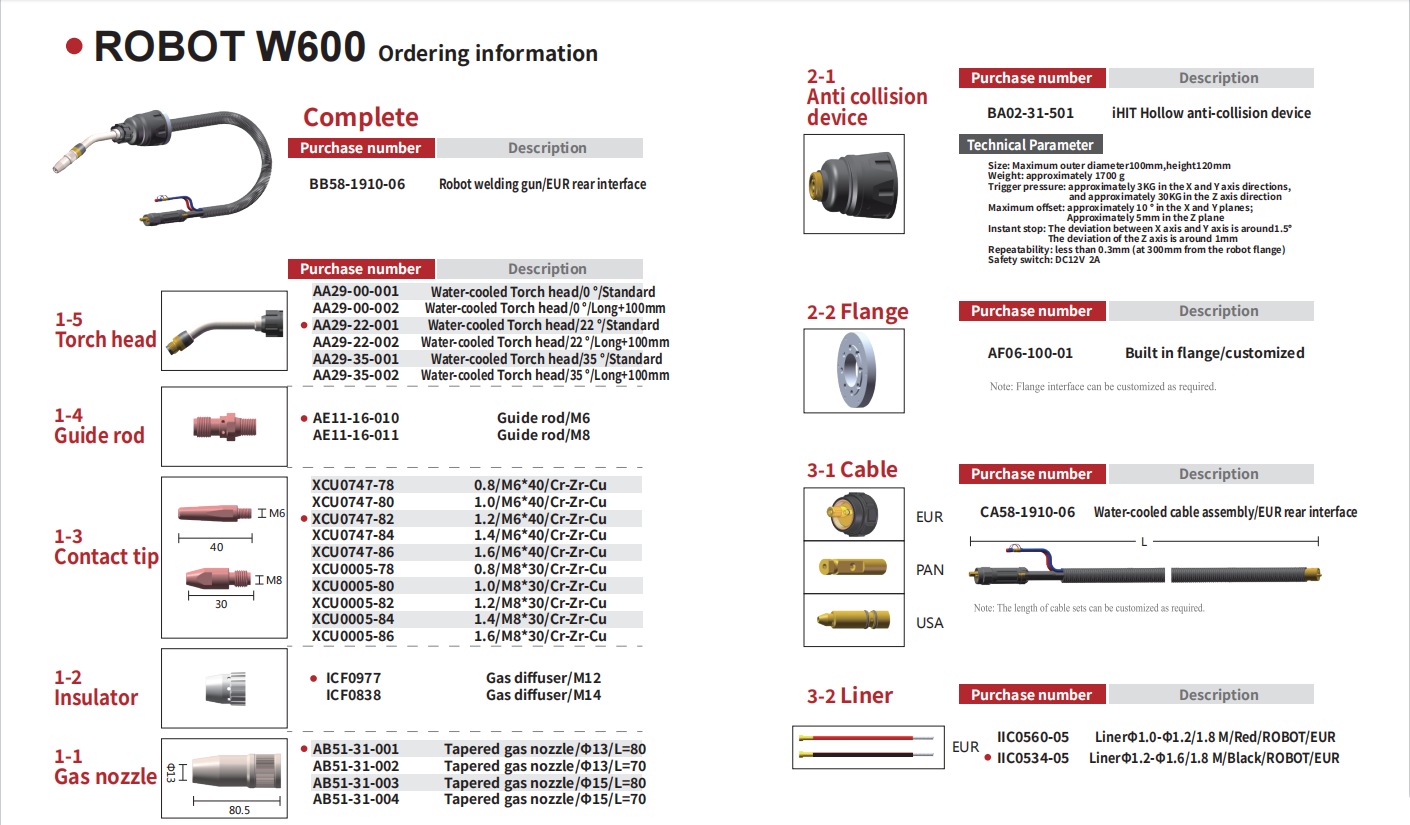

Complete

| Purchase number | Description | |||||

| BB58-1910-06 | Robot welding gun/EUR rear interface | ||||

| 1-5 | Torch head |  | AA29-00-001 | Water-cooled Torch head/0 °/Standard | ||

| AA29-00-002 | Water-cooled Torch head/0 °/Long+100mm | ||||

| AA29-22-001 | Water-cooled Torch head/22 °/Standard | ||||

| AA29-22-002 | Water-cooled Torch head/22 °/Long+100mm | ||||

| AA29-35-001 | Water-cooled Torch head/35 °/Standard | ||||

| AA29-35-002 | Water-cooled Torch head/35 °/Long+100mm | ||||

| 1-4 | Guide rod |  | AE11-16-010 | Guide rod/M6 | ||

| AE11-16-011 | Guide rod/M8 | ||||

| 1-3 | Contact tip |  | XCU0747-78 | 0.8/M6*40/Cr-Zr-Cu | ||

| XCU0747-80 | 1.0/M6*40/Cr-Zr-Cu | |||||

| XCU0747-82 | 1.2/M6*40/Cr-Zr-Cu | |||||

| XCU0747-84 | 1.4/M6*40/Cr-Zr-Cu | |||||

| XCU0747-86 | 1.6/M6*40/Cr-Zr-Cu | |||||

| XCU0005-78 | 0.8/M8*30/Cr-Zr-Cu | |||||

| XCU0005-80 | 1.0/M8*30/Cr-Zr-Cu | |||||

| XCU0005-82 | 1.2/M8*30/Cr-Zr-Cu | |||||

| XCU0005-84 | 1.4/M8*30/Cr-Zr-Cu | |||||

| XCU0005-86 | 1.6/M8*30/Cr-Zr-Cu | |||||

| 1-2 | Insulator |  | ICF0977 | Gas diffuser/M12 | ||

| ICF0838 | Gas diffuser/M14 | ||||

| 1-1 | Gas nozzle |  | AB51-31-001 | Tapered gas nozzle/Φ13/L=80 | ||

| AB51-31-002 | Tapered gas nozzle/Φ13/L=70 | |||||

| AB51-31-003 | Tapered gas nozzle/Φ15/L=80 | |||||

| AB51-31-004 | Tapered gas nozzle/Φ15/L=70 | |||||

| 2-1 | Anti collision device |  | BA02-31-501 | iHIT Hollow anti-collision device | ||

| 2-2 | Flange |  | AF06-100-01 | Built in flange/customized | ||

| 3-1 | Cable |  | EUR | CA58-1910-06 | Water-cooled cable assembly/EUR rear interface | |

| PAN |  |  | |||

| USA |  |  | |||

| 3-2 | Liner |  | EUR | IIC0560-05 | LinerΦ1.0-Φ1.2/1.8 M/RED/ROBOT/EUR | |

| IIC0534-05 | LinerΦ1.2-Φ1.6/1.8 M/BLACK/ROBOT/EUR | ||||

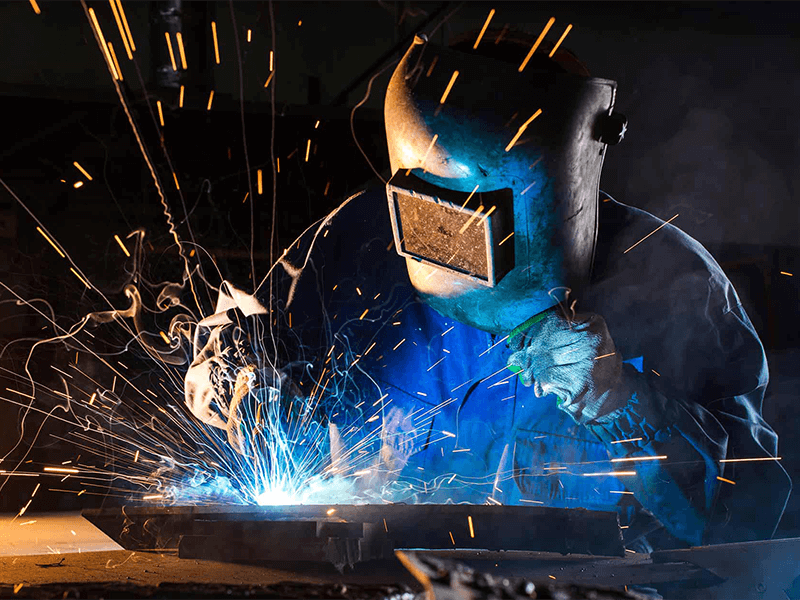

Are you ready to experience the special features of welding?

Boost Productivity Today – Experience how welder-centric engineering, industrial-grade consumables, and fatigue-reducing ergonomics elevate weld quality and operators' safety.

Next Steps

✓ Request Custom Quote: Tailored to your amperage, materials, and workflow

✓ Expert Support: Connect with welding engineers for technical guidance

Engineered for Results. Trusted Globally.