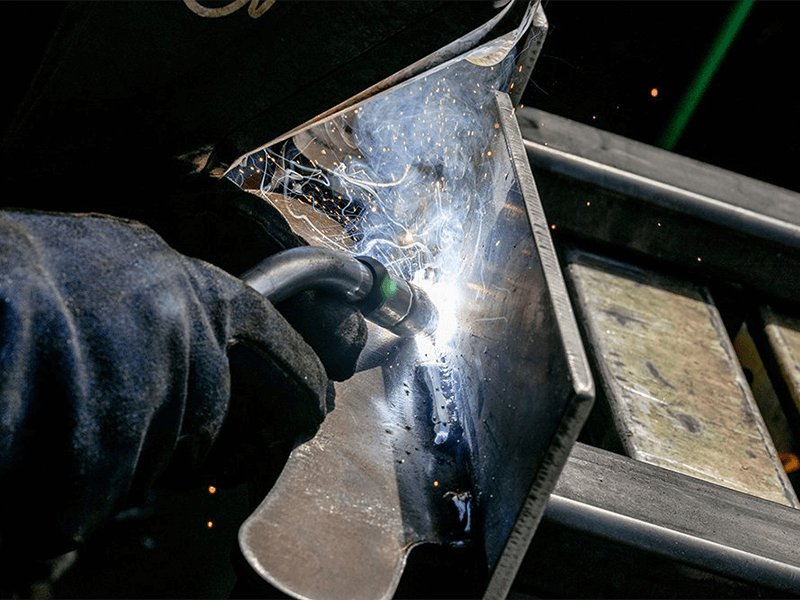

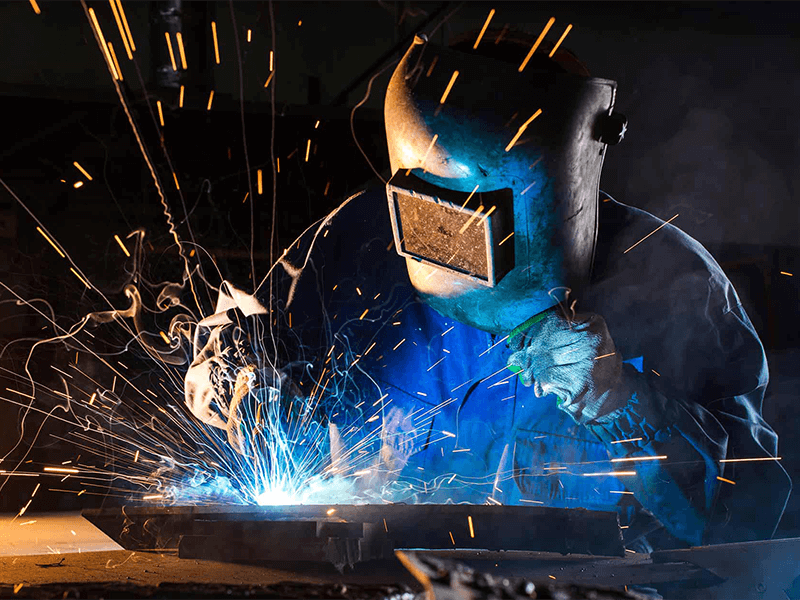

Welding is an art form that combines precision, skill, and a deep understanding of the material. Whether you're a seasoned professional or a beginner, mastering gun technique for MIG and TIG welding can elevate your work from functional to flawless. This article will delve into five essential techniques to help you achieve cleaner, stronger, and more aesthetically pleasing welds.

The importance of gun control is often overlooked during welding. The "cursive E" technique is crucial for MIG welding. By moving the gun in a smooth cursive "E" motion, you can create an even weld bead that mimics the coveted stacked coin look often seen in TIG welding. This technique requires patience and practice, but the result is well worth the effort. The key is to maintain a steady rhythm and avoid sudden movements to ensure even heat distribution and a smooth weld.

Another technique that can revolutionize MIG welding is the "half moon" method. This involves moving the gun in a semicircular pattern, which helps evenly distribute the filler material. The half-moon technique is particularly useful for thicker materials because it achieves better penetration and reduces the risk of weak spots. Like the cursive E, this method requires precision, but once mastered, it can significantly improve weld quality.

For those looking to improve their TIG welding skills, the gun angle is crucial. Holding the gun at a 15-degree angle provides optimal weld pool visibility and ensures proper shielding gas coverage. Deviating too far from this angle can result in contamination or uneven welds. The gun should be tilted slightly forward, with the electrode pointing in the direction of travel. This positioning allows for better control and a more stable arc, which is essential for high-quality TIG welding.

Distance control is another important factor in both MIG and TIG welding. For TIG welding, maintaining a constant arc length of approximately 1/8 to 3/16 inch is crucial. Too close, and the electrode may stick to the base material; too far, and the arc becomes unstable. In MIG welding, the distance between the gun and the workpiece affects penetration and weld bead shape. Experiment with different distances to find the optimal distance for your specific setup and material.

Finally, don't underestimate the power of your hands. While one-handed welding is possible, two-handed control offers unparalleled stability and precision. For MIG welding, one hand should hold the torch body, while the other supports the neck to ensure smooth movement. In TIG welding, use your non-dominant hand to feed the wire and your dominant hand to control the torch. This coordinated movement results in smoother, more even welds.

Welding is as much about technique as it is about equipment. Master these five torch techniques—cursive E-shaped, half-moon shape, torch angle, distance control, and two-handed operation—and you'll achieve professional-level results in both MIG and TIG welding. Remember, practice makes perfect. Take the time to hone these skills, and you'll soon see significant improvements in the quality and appearance of your welds.

In short, welding is a craft that requires patience, precision, and continuous learning. Whether you're pursuing the aesthetics of a stacked weld or the structural integrity of a deep penetration weld, these techniques will guide you to perfect results. Keep experimenting, stay curious, and never stop improving your skills. The journey to becoming a master welder is a marathon, not a sprint, and every weld bead you lay is an advancement in your craft.

Related Articles

Best Basic Welds

I find fillet welding to be one of the most practical welding methods, widely used for joining parts of metal and at right angles. "Fillet welds also play an important role in the construction of bridges, ships and various frames," Hicks said. Fillet welds are often the best choice to ensure the nec

The 5 Parameters of Welding

The five key welding parameters are current (40-200 amps), voltage (18-29 volts), travel speed (8-18 inches per minute), electrode type (e.g. E6013, E7018), and shielding gas mixture (e.g. 75% argon, 25% CO2). Table of Contents Switch Current Voltage Travel Speed Electrode Type and Size Shielding Ga

Are Cheap Gasless MIG Welders Any Good

Features of Cheap Gasless MIG WeldersWire Feed SpeedWire feed speed is crucial for cheap gasless MIG welders. Lower-priced models offer a wire feed speed range of 40-500 or 600 inches per minute. This still allows for adjustments based on weld thickness. Higher-end models have more precise controls