To operate a plasma cutter safely and effectively, you need a proper power source, appropriate safety gear, a well-ventilated workspace, necessary consumables, and a pre-cut checklist. This guide covers the key requirements for plasma cutting to help you achieve optimal results.

Plasma Cutter Power Requirements: Voltage and Phase Needs

Choosing the right plasma cutter power supply is critical for performance, efficiency, and the thickness of materials you can cut.

Voltage Input

110/120V: Suitable for light-duty home use; cuts materials up to 1/4 inch thick.

220/240V: Recommended for industrial applications; handles materials from 1/4 inch to 1 inch or more.

Many modern plasma cutting systems support dual-voltage operation for greater flexibility.

Phase and Power Options

Single-Phase: Common in residential settings; ideal for handheld and light-duty machines.

Three-Phase: Used in industrial environments for stable power delivery.

Generator Power: Essential for remote job sites; ensure output meets cutter requirements.

Direct AC Power: Most reliable where grid power is available.

Essential Safety Gear (PPE) for Plasma Cutting

Proper plasma cutter safety requires complete personal protective equipment (PPE) to guard against intense light, heat, and metal particulates.

Eye and Face Protection

Use a helmet or goggles with an appropriate shade level for amperage.

Protects against UV/IR radiation and flying debris – crucial for safe plasma cutter operation.

Heat and Flame Protection

Heat-resistant gloves (leather or Kevlar) protect hands from hot metal.

Flame-resistant clothing prevents burns from sparks or molten metal.

Respiratory Protection

A quality respirator filters harmful fumes and particles.

Ensure a tight seal for effective protection during plasma cutting.

Plasma Cutter Consumables: Tips, Electrodes, and Gas

Regularly replaced components are vital for maintaining plasma cutter performance and torch life.

Cutting Tips and Electrodes

Cutting tips focus the plasma stream; replace when worn.

Electrodes conduct current to the workpiece; check regularly for wear.

Gas Supply and Selection

Common gases: compressed air, nitrogen, argon, or mixtures.

Gas choice affects cut speed, quality, and material compatibility.

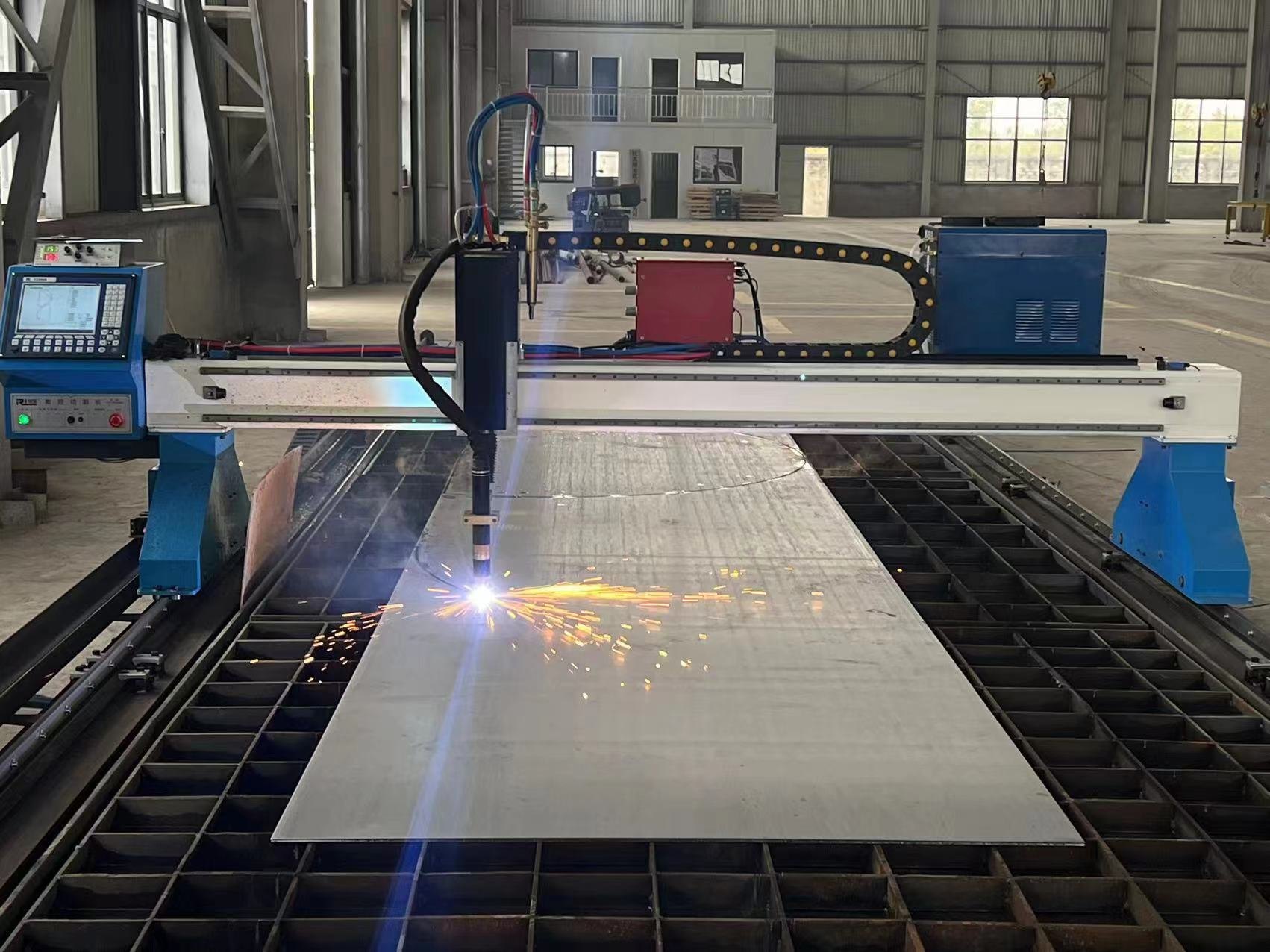

Workspace Setup for Optimal Plasma Cutter Operation

A properly arranged workspace enhances both plasma cutting safety and productivity.

Ventilation and Airflow

Use exhaust fans or fume extraction systems.

Maintain good airflow to protect respiratory health.

Workbench and Fire Safety

Use metal cutting tables with adjustable clamps.

Keep fire extinguishers nearby and store flammable materials safely.

Plasma Cutter Setup and Calibration

A Correct plasma cutter setup ensures optimal performance and extends equipment life.

Torch Alignment and Cutting Speed

Verify torch alignment through test cuts.

Adjust speed based on material thickness.

Gas Flow Settings

Set flow rate according to material and gas type.

Proper settings prevent cut quality degradation.

Operating Procedures: How to Operate a Plasma Cutter

Follow these steps for consistent, safe plasma cutter operation.

Pre-Cut Checklist

Verify all PPE is worn.

Ensure workspace is clear and ventilated.

Inspect consumables and equipment condition.

Cutting Technique

Maintain consistent torch height and steady movement.

Use guides or templates for complex shapes.

Plasma Cutter Maintenance and Troubleshooting Guide

Routine plasma cutter maintenance keeps your equipment running smoothly.

Common Issues & Solutions

Poor Cut Quality: Check tip condition and torch alignment.

Arc Ignition Failure: Inspect and replace the electrode if necessary.

Overheating: Ensure cooling systems are functional.

Maintenance Schedule

Daily: Inspect torch, cables, gas flow, and ventilation.

Weekly: Clean dust/debris; check ground clamp connection.

As Needed: Replace worn consumables (tips, electrodes).

By following these plasma cutter operation requirements, you'll ensure safe, efficient, and high-quality cutting performance.

Related Articles

What is the typical cost of mig welding?

Understanding MIG Welding Costs: A Detailed BreakdownThe cost of MIG welding can vary significantly depending on the scale and complexity of the project. For small DIY tasks, expenses may be relatively low, with basic equipment ranging from 400 to 2000. In contrast, large commercial or industrial pr

Metals Suitable for MIG Welding And Its Challenges

MIG welding, also known as Gas Metal Arc Welding (GMAW), is widely used across industrial and hobby applications due to its versatility and ability to join a variety of metals. However, some metals—including titanium alloys—pose challenges due to their reactive nature and other inherent properties.C

Introduction To Plasma Cutting Torch

Components of a Plasma Cutter TorchA plasma cutting torch consists of several key parts, including the electrode, nozzle, swirl ring, shield, and electrical and gas supply components. Each plays a critical role in ensuring precise and efficient cutting.Core Components1. ElectrodeThe electrode serves

Can A Plasma Cutter Burn Your Skin?

Yes, contact between a plasma cutter and skin will cause severe, immediate burns, resulting in deep tissue damage that requires urgent medical attention.The Science of Plasma Cutting: A Brief OverviewPlasma cutting is a process that utilizes a superheated, high-velocity stream of ionized gas (plasma

What Is The Basic Principle of Tig Welding?

TIG Welding: A Complete Guide to Equipment, Process & TechniquesTIG welding, also known as GTAW (Gas Tungsten Arc Welding), is a precision welding process that uses a non-consumable tungsten electrode to create an arc and shielding gas to protect the weld pool. This guide covers everything you need

How Thick Can A Plasma Cutter Cut?

How Thick Can a Plasma Cutter Cut?Plasma cutting thickness primarily depends on the machine's amperage, with high-end industrial models capable of cutting steel up to 2 inches thick.Types of Plasma Cutters:1. Handheld Plasma CuttersCompact and portable, these are ideal for DIY projects, metal fabric