Yes, contact between a plasma cutter and skin will cause severe, immediate burns, resulting in deep tissue damage that requires urgent medical attention.

The Science of Plasma Cutting: A Brief Overview

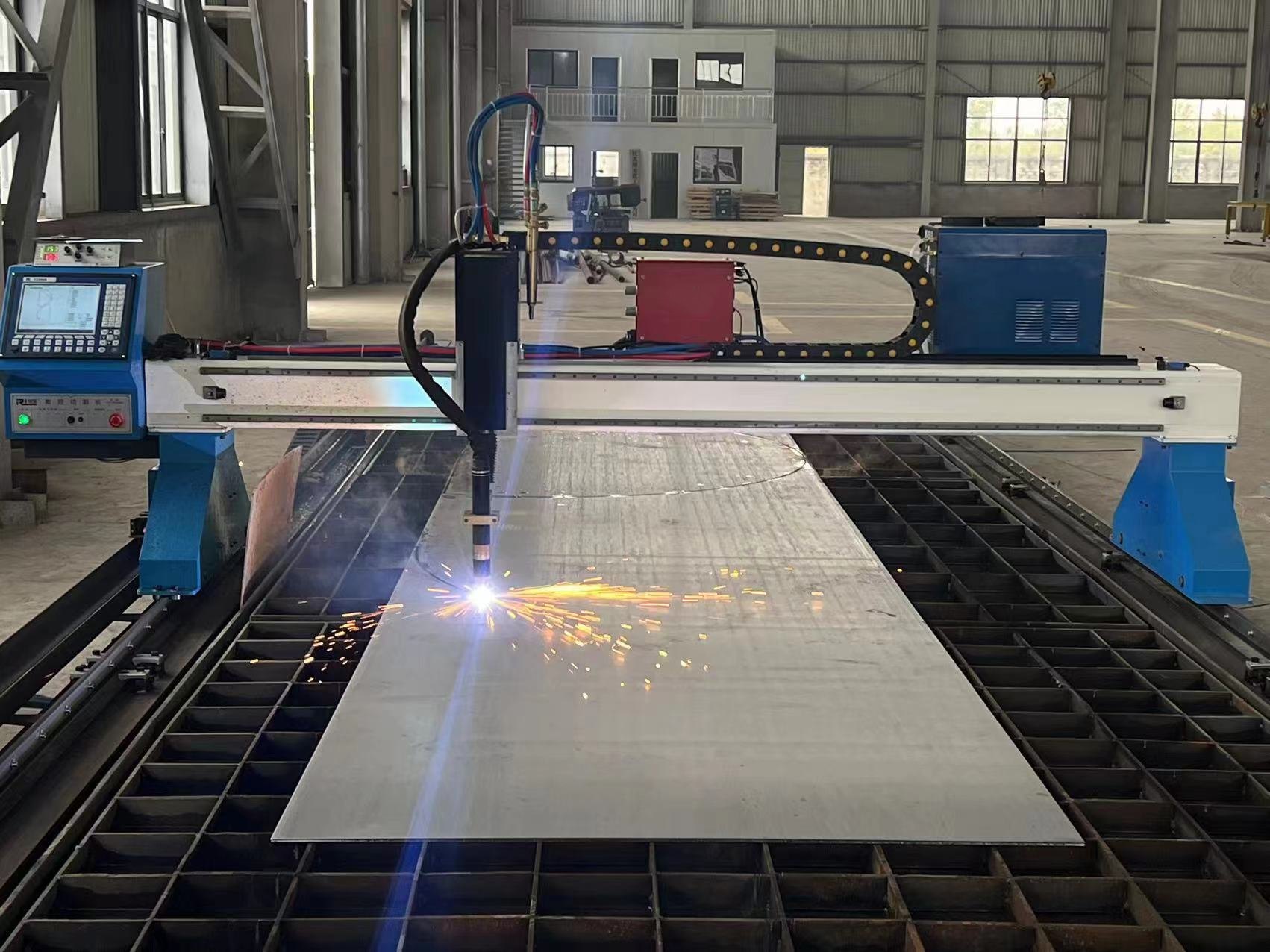

Plasma cutting is a process that utilizes a superheated, high-velocity stream of ionized gas (plasma) to slice through electrically conductive materials. The core component is the plasma torch, which features a negatively charged electrode. When this electrode is brought near the workpiece (which acts as the positive terminal), an electric arc is formed. This arc is forced through a constricting nozzle, focusing the plasma stream and dramatically increasing its temperature and velocity, creating an effective cutting tool.

The intense heat instantly melts the material, while the high-speed jet blows the molten metal away, leaving a clean cut. This method is valued for its precision, speed, and minimized heat-affected zone, making it a preferred technology in metal fabrication, automotive, and construction industries.

Materials Cut by Plasma

Plasma cutters are highly versatile and can process a wide range of conductive metals, including:

Steel: Effectively cuts carbon steel, stainless steel, and hardened steel.

Aluminum: Capable of cutting aluminum despite its high thermal conductivity.

Copper & Brass: More challenging but possible with the correct settings and gases.

Non-conductive materials like wood or plastic cannot be cut with this process.

Plasma Cutter Contact: Immediate and Long-Term Effects

Immediate Consequences of Skin Contact

Direct contact with the plasma arc causes instantaneous and severe deep-tissue burns due to the extreme temperature (which can exceed 30,000°F). The injury often extends far below the skin's surface, potentially damaging nerves, muscles, and even bone. Immediate, excruciating pain and a high risk of shock are common, necessitating emergency medical care. In extreme cases, such injuries can lead to long-term disability or amputation.

Long-Term Health Consequences

The long-term effects are serious and can include:

Significant scarring and contractures that limit mobility, especially near joints.

Permanent nerve damage leading to loss of sensation or chronic pain.

High risk of infection that can progress to sepsis if not properly treated.

Extensive rehabilitation, including physical therapy and multiple skin graft surgeries.

Psychological trauma following the accident.

Essential Safety Measures to Prevent Injury

1. Personal Protective Equipment (PPE)

Proper PPE is non-negotiable for plasma cutting:

Face and Eye Protection: A full-face welding helmet with the appropriate shade lens.

Hand Protection: Heavy-duty, flame-resistant gloves (e.g., leather).

Body Protection: Durable, flame-resistant clothing (jacket, pants) and safety boots to protect against sparks and heat.

2. Critical Safety Protocols

Training: Never operate a plasma cutter without proper training on its specific hazards and controls.

Workspace Safety: Ensure the work area is clean, dry, and free of flammable materials. Securely clamp the workpiece.

Equipment Check: Always verify that the machine and workpiece are properly grounded.

Emergency Preparedness: Keep a fully stocked first-aid kit and a fire extinguisher readily accessible.

Medical Response to Plasma Cutter Burns

First Aid Response

Ensure Safety: Immediately turn off the plasma cutter and separate the victim from the power source.

Cool the Burn: Flush the burn continuously with cool (not ice-cold) running water for at least 10-15 minutes.

Cover the Wound: Use a sterile, non-stick dressing to cover the area loosely.

Seek Immediate Medical Help: Call for emergency services immediately. Do not apply creams, ointments, or ice.

Related Articles

What is the typical cost of mig welding?

Understanding MIG Welding Costs: A Detailed BreakdownThe cost of MIG welding can vary significantly depending on the scale and complexity of the project. For small DIY tasks, expenses may be relatively low, with basic equipment ranging from 400 to 2000. In contrast, large commercial or industrial pr

Metals Suitable for MIG Welding And Its Challenges

MIG welding, also known as Gas Metal Arc Welding (GMAW), is widely used across industrial and hobby applications due to its versatility and ability to join a variety of metals. However, some metals—including titanium alloys—pose challenges due to their reactive nature and other inherent properties.C

Introduction To Plasma Cutting Torch

Components of a Plasma Cutter TorchA plasma cutting torch consists of several key parts, including the electrode, nozzle, swirl ring, shield, and electrical and gas supply components. Each plays a critical role in ensuring precise and efficient cutting.Core Components1. ElectrodeThe electrode serves

What Is The Basic Principle of Tig Welding?

TIG Welding: A Complete Guide to Equipment, Process & TechniquesTIG welding, also known as GTAW (Gas Tungsten Arc Welding), is a precision welding process that uses a non-consumable tungsten electrode to create an arc and shielding gas to protect the weld pool. This guide covers everything you need

How Thick Can A Plasma Cutter Cut?

How Thick Can a Plasma Cutter Cut?Plasma cutting thickness primarily depends on the machine's amperage, with high-end industrial models capable of cutting steel up to 2 inches thick.Types of Plasma Cutters:1. Handheld Plasma CuttersCompact and portable, these are ideal for DIY projects, metal fabric

What Voltage Is Needed for Plasma Cutting?

Plasma cutting machines require varying voltage levels, typically ranging from 110V for small-scale tasks to 600V for industrial applications.Plasma Cutting BasicsUnderstanding the fundamentals of plasma cutting is essential for both beginners and experienced operators. This process relies on key co