Innotec Welding Committed To The Manufacture & Service Of Hight-Quality

A Professional Manufacturer Integrating R&D, Production And Sales Of Welding Torches, Cutting Torches, Quick Plugs/Sockets And Their Accessories.

19 Years Of Welding Technology Accumulation

Established in 2006, Innotec is a professional manufacturer and service provider specializing in research, production, and sales of Welding Torches.

Serving 2000+ Industrial Enterprises

Due to our extensive reach and impact, we proudly serving over 2,000 industrial enterprises across diverse sectors.

113 Technical Patents

Innotec invests 20% of its profits in research and development every year. Currently, we have applied for 113 technical patents.

2 Major Service Centers Nationwide

We focus on innovating and creating valve together with our business partners.

35+ Highly Sophisticated R&D Personnel

Innotec maintains a leading position in research and development capabilities in the chinese welding sector.

40,000㎡ Factory Area

with an area coverage of 40,000 m², Innotec now has over 300 machine tools,our yearly production capacity is over 2,500,000 pcs.

Ergonomic MIG welding guns ensure low-spatter, high-speed joins for steel, aluminum, and stainless steel.

Precision TIG welding torches deliver clean, spatter-free welds on stainless steel, aluminum, and titanium.

Industrial-grade plasma cutting torches ensure precision, high-speed slicing on steel, stainless steel, and aluminum.

IPT

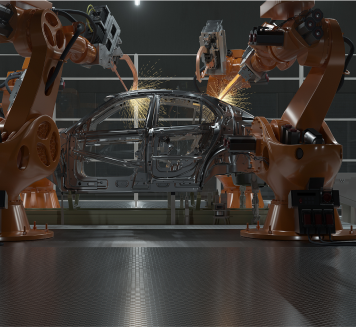

Robotic welding torches ensure precision high-speed automation for automotive and heavy industry.

Differentiation

Product Performance Differentiation Specialist Of You

Targeting three critical operations in pipeline construction — circumferential seam welding for high-strength pipelines, hot tapping under pressure, and precision bevel cutting — we offer a dual-standard process system certified to both API and ASME.

Focusing on three critical scenarios in shipbuilding — longitudinal stiffener welding on shell plates, circumferential seam welding during grand block assembly, and precision cutting of thick plates...

Addressing three heavy-fume industrial welding conditions — enclosed space welding, high-current continuous operations, and heavy component manufacturing — we offer fume extraction solutions fully compliant with EN 1093-5 and ISO 15012 standards.

As the wind power industry moves toward larger-scale and offshore development, welding and cutting technologies face unprecedented challenges: tower heights exceeding 150 meters, single-unit capacities reaching 15 MW, and harsher offshore corrosion environments.

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Welding requirement communication:Professional welding sales

Latest Technology Trends

Customer Case Library

Latest Technology Trends

Knowledge Base Entrance

Latest News

Dynamic Content Area

-

In 2013, Shanghai Innotec Welding Technology Co., Ltd. was awarded Shanghai’s ”Specialized, Sophisticated, Differentiated, Innovative (SSDI) SME” title, becoming a welding equipment manufacturer recognized for cutting-edge R&D and niche market excellence. This accreditation validated its leadershipINNOTEC NEWS

In 2013, Shanghai Innotec Welding Technology Co., Ltd. was awarded Shanghai’s ”Specialized, Sophisticated, Differentiated, Innovative (SSDI) SME” title, becoming a welding equipment manufacturer recognized for cutting-edge R&D and niche market excellence. This accreditation validated its leadershipINNOTEC NEWS

An Important Step In The Overall Development

Welcome To Email Us!